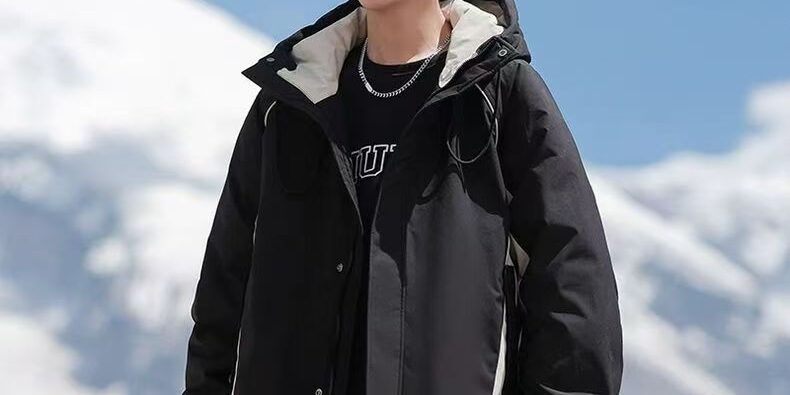

Introduction: Why Customization Matters in Men’s Puffer Jackets

Global buyers know that men’s puffer jackets are a seasonal must-have. But in today’s market, selling generic designs is no longer enough. Retailers want their own identity reflected in the products they sell. That’s why working with a custom men’s puffer jackets factory is becoming the preferred sourcing option. By combining manufacturing capacity with design flexibility, factories help brands build collections that stand out.

Step 1: Define Your Customization Goals

Before approaching a supplier, buyers should have a clear idea of what they want. Typical goals include:

-

🎨 Unique Designs – Adjust patterns, trims, or fabric finishes.

-

🧵 Private Label Branding – Add logos, woven labels, or packaging.

-

🌱 Sustainable Materials – Choose recycled insulation or eco-friendly fabrics.

-

📦 MOQ Planning – Decide how many units you need for the first bulk order.

By outlining these needs early, communication with the men’s puffer jackets factory will be smoother and more efficient.

Step 2: Choosing the Right Factory Partner

Not all factories are equal. To ensure long-term success, look for:

-

✅ Experience with International Buyers – Proven history of OEM/ODM services.

-

✅ Strong Quality Control – Factories with strict QC ensure consistent jackets.

-

✅ Flexible Capacity – Ability to handle both small test orders and large seasonal volumes.

-

✅ Global Compliance – Meeting safety and textile standards in your target markets.

Many buyers trust Men’s Puffer Jackets Manufacturers for their ability to combine bulk capacity with flexible customization.

Step 3: Customization Options You Can Request

When working with Custom Puffer Jacket Manufacturers, buyers can request a wide range of options:

-

Adding corporate or retail branding to labels and hangtags

-

Selecting different insulation (synthetic vs. natural down alternatives)

-

Developing seasonal collections with unique colors or patterns

-

Tailoring fits for specific regions or demographics

This flexibility helps retailers transform wholesale orders into exclusive brand collections.

Step 4: Effective Communication with Factories

Strong communication is critical. Buyers should:

-

📑 Provide clear tech packs, including sketches, fabrics, and measurements.

-

🧪 Request samples before mass production to confirm design accuracy.

-

⏰ Agree on timelines for sampling, production, and shipping.

-

💬 Maintain regular updates to ensure alignment throughout the process.

Clear communication avoids costly mistakes and builds trust between buyer and supplier.

Step 5: Scaling from Sample to Bulk Orders

Once samples are approved, the next step is bulk procurement. Reliable Puffer Jacket Manufacturers can scale production to thousands of units while maintaining the same quality. Buyers benefit from:

-

Lower cost per unit with bulk orders

-

Consistent branding across shipments

-

Export packaging designed for international logistics

-

Flexible shipping terms to match business needs

Conclusion: Building Value Through Custom Factories

Working with a custom men’s puffer jackets factory allows retailers to go beyond basic supply. It’s about building collections that reflect brand identity, appeal to market trends, and deliver consistent quality. With the right partner, buyers can achieve both differentiation and efficiency, securing long-term growth in the competitive apparel industry.

By aligning with trusted factories, retailers gain not only jackets but also a reliable foundation for future expansion.